Product type: WB7

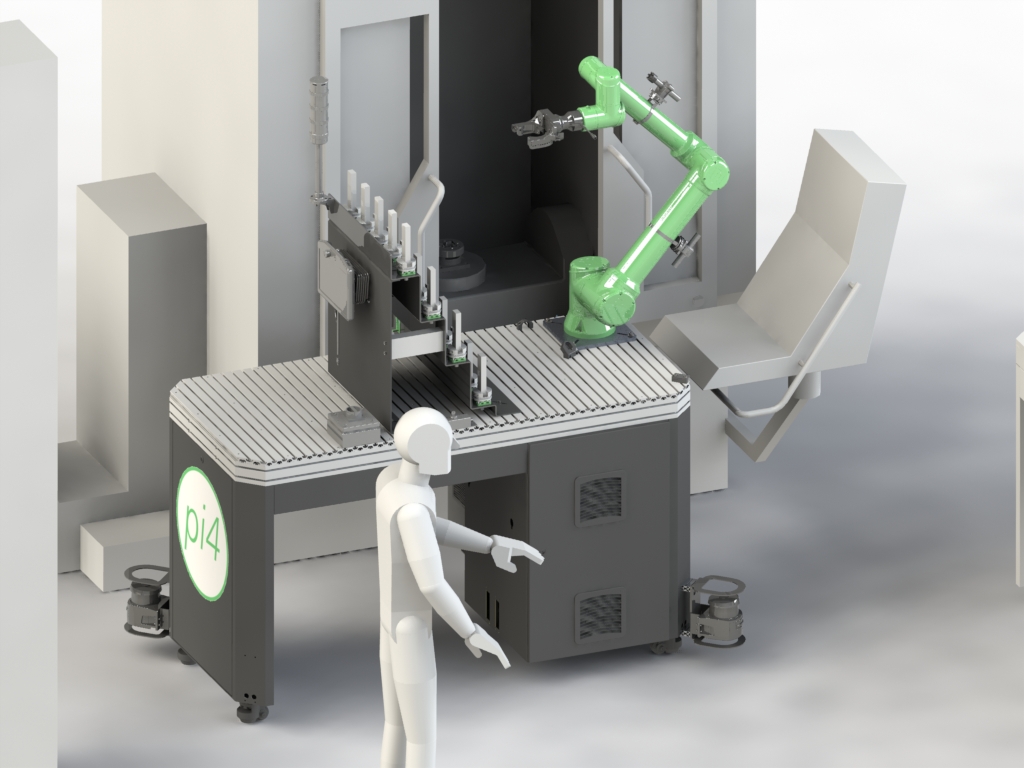

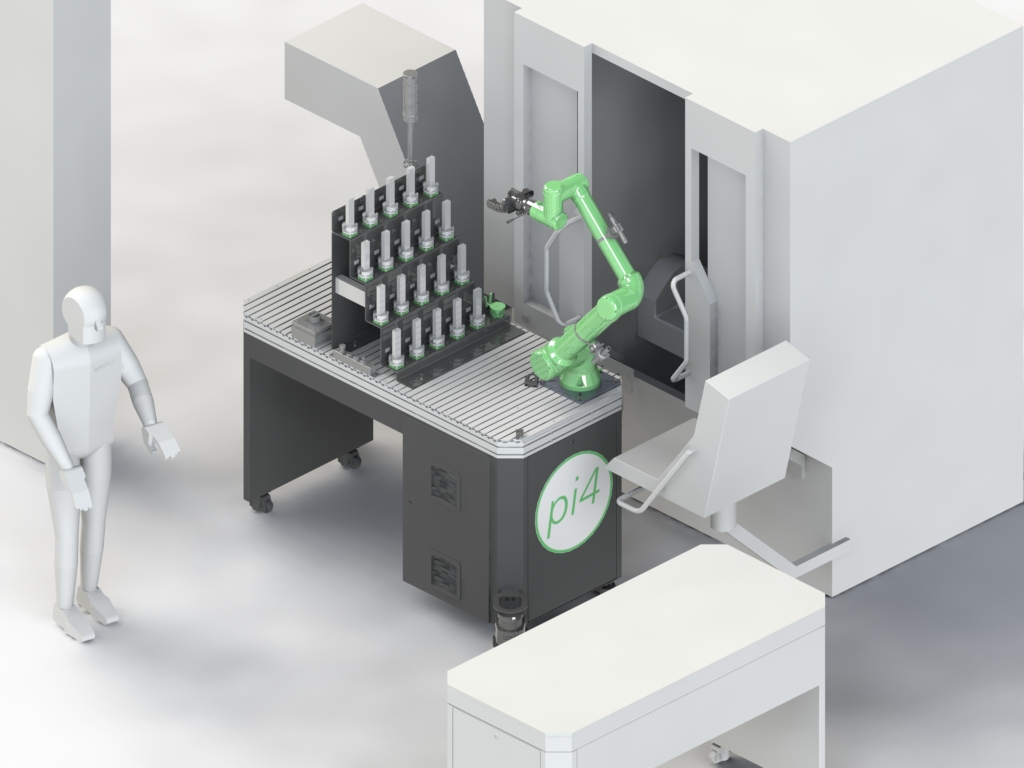

Robot for loading machines

With the help of the Workerbot7, the loading of machines such as a lathe or milling machine can be automated. The unmanned 24/7 operation allows a better utilization of these machines. The operator only has to place new parts in the robot’s memory, and the robot does everything else automatically.

The robot uses its gripper to open and close the machine doors. With the aid of a gripper extension, the robot also takes care of clamping, releasing and blowing off the workpiece carriers.Thanks to the sensitivity of the robot and a special guide on the gripper, the robot system can automatically calibrate itself to the new position, even if the table and the new loading position in the machine are detected.

Features

- large table for own setups

- theater-like storage area for products

- gripper with gripping force monitoring

- blow-off function in the gripper for cleaning the products

- opening of machine doors by the robot possible

- operation via touch panel

- suitable for robots Universal Robot UR3e, UR5e, UR10e and UR16e

Safety features

- approved safety laser scanner for monitoring the working area around the machine

- standard-compliant main switch

- operating mode selector switch

- emergency stop button

- separate safety control PNOZ

- Safety planes for limiting the robot working range

- Speed monitoring of the robot movements